- Course No E – 1105

- PDH Units 4.00

No data found for Custom Course Number

No data found for Custom Course Units

- Course No E – 1105

- PDH Units 4.00

Intended Audience: mechanical, civil and chemical, environmental, and industrial engineers

PDH UNITS: 4

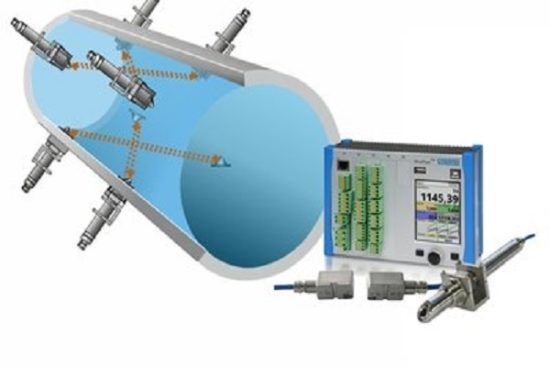

This course is about measurement of the flow rate of a fluid flowing under pressure in a closed conduit. The closed conduit is often circular, but also may be square or rectangular (such as a heating duct) or any other shape. The other major category of flow is open channel flow, which is the flow of a liquid with a free surface open to atmospheric pressure. Measurement of the flow rate of a fluid flowing under pressure, is carried out for a variety of purposes, such as billing for water supply to homes or businesses or, for monitoring or process control of a wide variety of industrial processes, which involve flowing fluids. Several categories of pipe flow measurement devices will be described and discussed, including some associated calculations. This course is intended primarily for mechanical, civil, chemical, environmental, and industrial engineers. Upon completing this course, you'll gain knowledge about twelve different types of meters for measuring fluid flow rate in a closed conduit and the primary calculations for differential pressure meters and pitot tubes. You'll also learn the general principles of operation and the advantages and disadvantages of each.

Learning Objectives

- Calculate flow rate from measured pressure difference, fluid properties, and meter parameters, using the provided liquid flow equations for venturi, orifice, and flow nozzle meters.

- Determine which type of ISO standard pressure tap locations are being used for a given orifice meter.

- Compute the orifice coefficient, Co, for specified orifice and pipe diameters, pressure tap locations and fluid properties.

- Estimate the density of a specified gas at specified temperature and pressure using the Ideal Gas Equation.

- Calculate the velocity of a fluid for given pitot tube reading and fluid density.

- Determine the general configuration and principle of operation of rotameters and positive displacement, electromagnetic, target, turbine, vortex, ultrasonic, Coriolis mass flow, and thermal mass flow meters.

- Identify the characteristics of the types of flow meters as summarized in Table 2 of the course content.

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.