- Course No E – 1884

- PDH Units: 4

No data found for Custom Course Number

No data found for Custom Course Units

- Course No E – 1884

- PDH Units: 4

Intended Audience: Oil, Gas and Mechanical Engineers, and all engineers interested in Oil Pumping.

PDH UNITS: 4

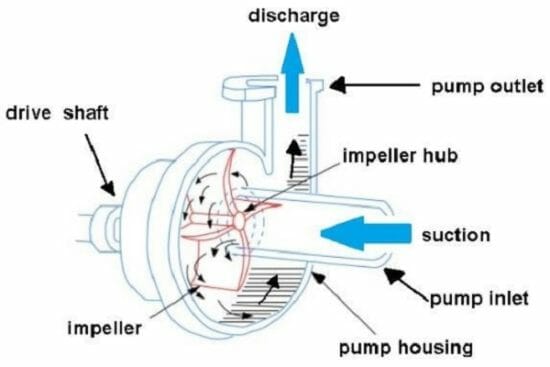

This course is presented by a program manager for a viscous (or heavy) oil pumping system (VOPS). An overview of the concepts of pumping heavy oil with focus on use of water lubrication. Adequate amounts of water are injected into the heavy oil flow to create an annulus or ring that forms around the heavy oil. The annulus delivers a small amount of water at high pressure into the oil stream. This creates a water ring that contacts the pipe or hose wall thereby reducing friction compared to pumping oil only. The reduction in friction causes less of a pressure drop or loss. This type of oil pumping application is called core annular flow (CAF) since the lubrication water forms an annulus or ring around the oil core. This course will provide an overview of the governing equations of core annular flow’s behavior. Pressure drop and stability of the core annular flow stability will be addressed. Because of the complexity of two liquids (water and oil) flowing together, core annular flow systems are designed typically using both quantitative and experimental methods. Core annular flow systems represent an extraordinarily complex field dependent on advanced numerical methods, computer aided design, and results from field experiments. A synopsis is provided of core annual flow research such as numerical analysis and experimentation results on minimum oil flow velocity and Reynolds number. This is not an advanced fluid mechanics course. It is presented so that an engineer with a limited fluid mechanics background can understand it. There will be some quantitative explanations and a larger amount of qualitative description. However, there will be more practical emphasis on the configuration and operation of a heavy oil pumping system. The primary focus will be on the United States Navy’s viscous oil pumping system (VOPS) as a real-world example or application. This includes a discussion of the configuration and performance of viscous oil pumping system’s positive displacement screw pump.

Learning Objectives:

At the successful conclusion of this course, you will learn the following knowledge and skills:- After attending this course, you will know the principles and concepts of pumping heavy oil with water lubrication. You will learn to apply calculations such as calculating the Reynolds number for a composite flow of oil and water, determining the friction factor by use of the Blasius equation, estimating pump power, and calculating a performance improvement factor for a pump that applies core annular flow. You will gain knowledge of core annular flow concepts like American Petroleum Institute gravity, water injection, grade lines, pressure drop, oil fouling, slip, and water holdup fraction.

- You will understand the configuration of a heavy oil pumping system. This includes focus on the screw pump as well as pumping principles like back pressure, static suction lift, and positive versus nonpositive displacement. Concepts like shear thinning to reduce viscosity will be presented.

- You will be able to apply preliminary methods with planning a CAF system based on past research and experimentation results. By applying CAF concepts, you will calculate volumetric flow rates for oil and lubrication water.

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.