Subtotal: $75.00

- Course No E – 1867

- PDH Units: 6

No data found for Custom Course Number

No data found for Custom Course Units

- Course No E – 1867

- PDH Units: 6

Intended Audience: Electrical, Mechanical, and Environmental engineers

PDH UNITS: 6

Baghouse filters are commonly used to capture dust and other airborne particulates from industrial processes such as cement, metal, chemical, pharmaceutical, printing, woodworking, food processing, and construction. Industry-specific state OSHA rules and the EPA regulations mandate that businesses adhere to strict indoor air quality requirements and limit dust, smoke, and fume emissions into the atmosphere. By far the most prevalent type of air pollution control equipment is the baghouse type dust collector that serves a critical role in helping companies meet these criteria and improve both interior and outdoor environments by capturing a large percentage of particles generated by industrial operations. Many aspects must be considered while designing an industrial baghouse, including space constraints, cleaning methods, fabric construction, air-to-cloth ratio, and many construction features like inlet position, hopper design, and dust discharge mechanisms. This 6-hour course will go through the most important elements to consider when choosing the best dust collector for your application. The target audience for this course is electrical, mechanical, and environmental engineers, plant layout designers, health & safety personnel, operation, maintenance, and facilities personnel responsible for industrial operations and infrastructure. Please note that this course will focus solely on fabric dust collector designs and will not cover other types of collectors such as wet scrubbers or electrostatic precipitator dust collectors.

Learning Objectives:

At the successful conclusion of this course, you will learn the following knowledge and skills:- Introduction to various types of dust collectors

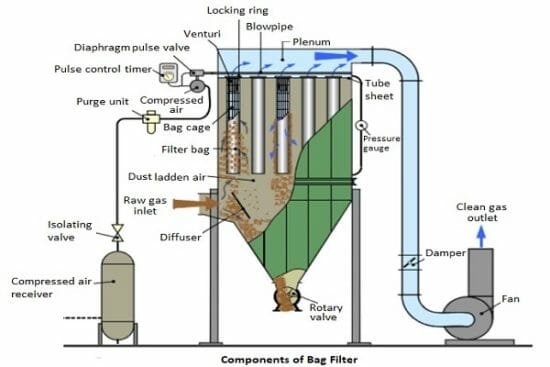

- Identify and describe the main components of a Baghouse type dust collectors

- Identify and describe the operation of shaker baghouses, reverse air baghouses and the pulse jet baghouses

- Understand the pros and cons of Fabric Type Baghouse v/s Cartridge Pleated Filter

- List important variables for baghouse design

- Define the terms "air-to-cloth ratio," "pressure drop," "grain loading," and "can velocity"

- Design guidelines for collection hoods and ductwork

- Design guidelines for collection hopers and fans

- Estimate the cloth area needed for a given gas process flow rate

- Design guidelines to prevent baghouse explosions and fires

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.

E - 1125 Centrifugal and Positive Displacement Pump Basics

E - 1125 Centrifugal and Positive Displacement Pump Basics