- Course No E – 1804

- PDH Units: 3

No data found for Custom Course Number

No data found for Custom Course Units

- Course No E – 1804

- PDH Units: 3

Intended Audience: Mechanical Engineers and construction managers

PDH UNITS: 3

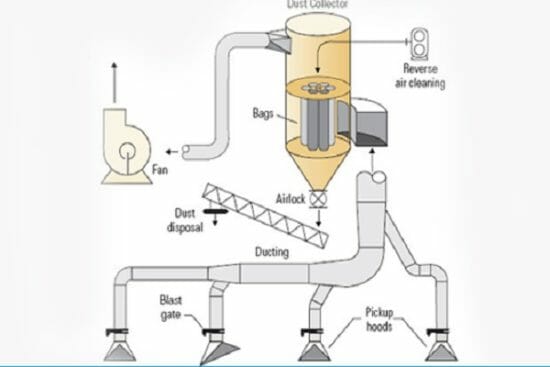

This course discusses the cyclone which is a widely used type of particulate collection device in which dust-laden gas enters tangentially into a cylindrical or conical chamber and leaves through a central opening. The resulting vortex motion or spiraling gas flow pattern creates a strong centrifugal force field in which dust particles, by virtue of their inertia, separate from the carrier gas stream. They then migrate along the cyclone walls by gas flow and gravity and fall into a storage receiver. In a boiler or incinerator installation this particulate is composed of fly-ash and unburned combustibles such as wood char. This course will give you technical guidance you can apply when designing and constructing air pollution control systems.

Learning Objectives:

At the successful conclusion of this course, you will learn the following knowledge and skills:- Learn about the most commonly used cyclone which is the medium efficiency, high gas throughput (conventional) cyclone. Cyclones of this type are used primarily to collect coarse particles when collection efficiency and space requirements are not a major consideration. Collection efficiency for conventional cyclones on 10 micron particles is generally 50 to 80 percent;

- Learn about high cyclone collection efficiency (80-95 percent) when it is a primary consideration in selection. A unit of this type is usually smaller in diameter than the conventional cyclone, providing a greater separating force for the same inlet velocity and a shorter distance for the particle to migrate before reaching the cyclone walls. These units may be used singly or arranged in parallel or series;

- Learn when very large gas volumes must be handled and high collection efficiencies are needed a multiple of small diameter cyclones are usually nested together to form a multi cyclone. A unit of this type consists of a large number of elements joined together with a common inlet plenum, a common outlet plenum, and a common dust hopper. The multi cyclone elements are usually characterized by having a small diameter and having axial type inlet vanes;

- Learn how cyclones may be operated wet in order to improve efficiency and prevent wall buildup or fouling. Efficiency is higher for this type of operation because dust particles, once separated, are trapped in a liquid film on the cyclone walls and are not easily re-entrained;

- Learn how a particle size distribution curve shows the weight of the particles for a given size range in a dust sample as a percent of the total weight of the sample. Particle size distributions are determined by gas sampling and generally conform to statistical distributions.

- Learn how energy requirements in the form of fan horsepower are directly proportional to the volume of gas handled and the cyclone resistance to gas flow. Fan energy requirements are estimated at one quarter horsepower per 1000 cubic feet per minute (cfm) of actual gas volume per one inch, water gauge, pressure drop., and

- Learn how cyclones are used as particulate collection devices when the particulate dust is coarse, when dust concentrations are greater than 3 grains per cubic foot (gr/ft3), and when collection efficiency is not a critical requirement.

Course Reviews

5

- 5 stars0

- 4 stars0

- 3 stars0

- 2 stars0

- 1 stars0

No Reviews found for this course.

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.