- Course No E – 1402

- PDH Units 3.00

No data found for Custom Course Number

No data found for Custom Course Units

- Course No E – 1402

- PDH Units 3.00

Intended Audience: Mechanical Engineers

PDH UNITS: 3

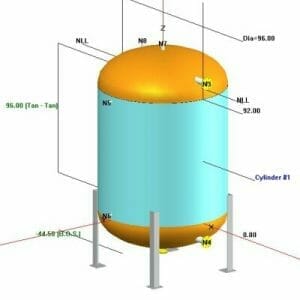

This course provides guidance for the inspection of steam and hot water boilers and unfired pressure vessels. In addition to boilers, inspection and testing is discussed for carbon dioxide and liquid petroleum gas vessels, heat exchangers, and deaerators. Course Outline 1. INSPECTION AND TEST FREQUENCIES 2. UNFIRED PRESSURE VESSELS 3. BOILER INSPECTIONS 4. UNFIRED PRESSURE VESSEL INSPECTIONS 5. PRESSURE TESTS 6. OPERATIONAL TESTS 7. REPAIRS AND ALTERATIONS 8. INSPECTION CERTIFICATES AND REPORTS 9. MAXIMUM ALLOWABLE WORKING PRESSURE This course will give mechanical engineers an introduction to the fundamentals of inspecting and testing operational unfired pressure vessels and boilers.

Learning Objectives

At the successful conclusion of this course, you’ll be able to identify and discuss:- Learn the required frequency of inspection and testing of heat exchangers operating over and under 250 psig;

- Learn the fundamentals of pressure test; Learn when hydrostatic testing is required;

- Learn about special inspections required for steam boilers;

- Learn the special considerations when repairs are made to steam boilers as a result of inspection and testing;

- Learn the requirements for boilers testing and inspection in dry layup; and

- Learn about the appropriate codes that apply to testing and inspection.

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.

Ethics Courses

E – 1840 Engineering Ethics: The Collapse of the FIU Pedestrian Bridge. Design & Ethical Failuresby Dr. Abolhassan Astaneh-Asl, Professor Emeritus. Ph.D., PE

E – 1865 Engineering Ethics: The Cases of Challenger and Columbia Shuttle Disasters; “Hold Safety Paramount” to Prevent Loss of Lifeby Dr. Abolhassan Astaneh-Asl, Professor Emeritus. Ph.D., PE