Subtotal: $75.00

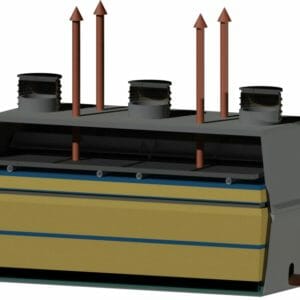

E – 1557 Control & Instrumentation for Steam Power Plants

$75.00

Courses Included

This publication provides an introduction to instrumentation and controls for steam boilers and power generating plants.

Course Outline

1. TYPES OF CONTROLS AND CONTROL SYSTEMS

2. STEAM POWER PLANT CONTROLS

3. SAFETY DEVICES AND INTERLOCKS

4. CONTROL LOOPS

5. FLOW METERS

6. PRESSURE GAUGES

7. TEMPERATURE SENSORS

8. TRANSMITTERS

9. RECORDERS

10. CONTROLLERS

11. OPERATORS

12. POSITIONERS

13. CONTROL ROOM

This course will give electrical and mechanical engineers and other professional engineers and managers advice and recommendations on steam power plant instrumentation and controls.

Description

This publication provides an introduction to instrumentation and controls for steam boilers and power generating plants.

Course Outline

1. TYPES OF CONTROLS AND CONTROL SYSTEMS

2. STEAM POWER PLANT CONTROLS

3. SAFETY DEVICES AND INTERLOCKS

4. CONTROL LOOPS

5. FLOW METERS

6. PRESSURE GAUGES

7. TEMPERATURE SENSORS

8. TRANSMITTERS

9. RECORDERS

10. CONTROLLERS

11. OPERATORS

12. POSITIONERS

13. CONTROL ROOM

This course will give electrical and mechanical engineers and other professional engineers and managers advice and recommendations on steam power plant instrumentation and controls.

- Learn how analog control is the representation of numerical quantities by means of physical variables such as current, air pressure, voltage, rotation, resistance, electromagnetic field (EMF), etc.;

- Learn about microprocessor-based control stations that are a digital stand alone single controller type, or a split-architecture control system offering powerful, configurable control capability on a modular basis.;

- Learn how direct digital control can perform all of the control functions, operator displays and graphics, reports and calculations for efficiency and controller tuning, or a computer can be used as a supervisory control for analog control system, microprocessor based control units, or as a data logger with graphic displays.;

- Learn why maintenance and calibration is a necessity regardless of the type of control equipment being used;

- Learn the function of combustion control which comprises a series of devices on a boiler developed to satisfy steam demands automatically and economically by controlling furnace combustion rates through adjustments of the burning components while maintaining a constant set point (such as a fixed but adjustable pressure or temperature) and an optimum (adjustable) ratio of fuel to air.; and

- Learn why steam turbine controls should be supplied with the rapid advancement of electronics, and an electrohydraulic control (ehc) system.

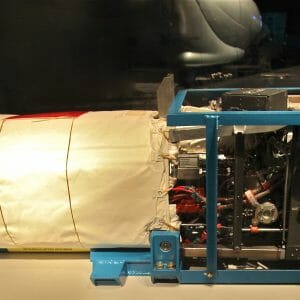

E - 1124 Fuel Cells–Green Power

E - 1124 Fuel Cells–Green Power