TP – 1302 An Introduction to Detail and Weld Inspection of Steel Hydraulic Structures for Professional Engineers

$4.99

Description

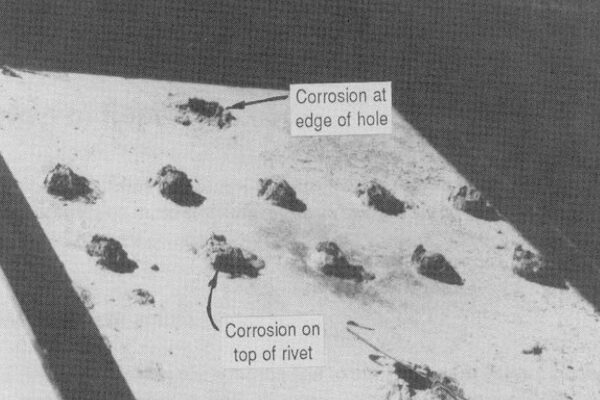

This technical paper summarizes appropriate inspection procedures, nondestructive testing (NDT) inspection methods, required inspector qualifications, and code acceptance criteria for defects in new weldments. If distressed structural members or connections are identified in the periodic inspection or deterioration in structural performance is assessed from the initial evaluation, then the entire structure should receive a more detailed inspection. Detailed inspections may also be used as part of a damage-tolerance fracture control plan. This fracture control concept is based on the fact that presence of crack like discontinuities in the structural members or connections does not necessarily mean the end of the service life of the structure. An integrated approach using scheduled inspections on the flawed members and analysis of fracture/fatigue resistance of the same members can assure satisfactory structural performance. The cost for repair or replacement of the flawed members can therefore be balanced against the inspection cost.