-

×

E - 1105 Flow Measurement in Pipes and Ducts

2 × $100.00

E - 1105 Flow Measurement in Pipes and Ducts

2 × $100.00 -

×

E - 1106 Fundamentals of Heat Exchangers

2 × $50.00

E - 1106 Fundamentals of Heat Exchangers

2 × $50.00 -

×

E - 1114 Hydraulic Jumps and Supercritical & Non-uniform Flow

2 × $75.00

E - 1114 Hydraulic Jumps and Supercritical & Non-uniform Flow

2 × $75.00 -

×

E - 1125 Centrifugal and Positive Displacement Pump Basics

3 × $75.00

E - 1125 Centrifugal and Positive Displacement Pump Basics

3 × $75.00 -

×

E - 1111 Disinfection with Peroxone

3 × $50.00

E - 1111 Disinfection with Peroxone

3 × $50.00 -

×

E - 1104 Domestic Wastewater Treatment Overview

2 × $75.00

E - 1104 Domestic Wastewater Treatment Overview

2 × $75.00 -

×

E - 1123 Concrete Methods and principles - Full 8 Hours Course

2 × $200.00

E - 1123 Concrete Methods and principles - Full 8 Hours Course

2 × $200.00 -

×

E - 1130 Steel Design - Full 8 Hours course - Updated to AISC 14th edition

2 × $200.00

E - 1130 Steel Design - Full 8 Hours course - Updated to AISC 14th edition

2 × $200.00 -

×

E - 1103 Hydraulic Design of Storm Sewers with Excel

1 × $100.00

E - 1103 Hydraulic Design of Storm Sewers with Excel

1 × $100.00 -

×

E - 1109 Design of Small Water Systems

1 × $150.00

E - 1109 Design of Small Water Systems

1 × $150.00 -

×

E - 1113 Manning Equation - Open Channel Flow using Excel

1 × $100.00

E - 1113 Manning Equation - Open Channel Flow using Excel

1 × $100.00 -

×

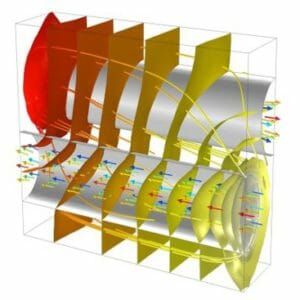

E - 1108 Heat Transfer Review for Engineers

2 × $75.00

E - 1108 Heat Transfer Review for Engineers

2 × $75.00 -

×

E - 1115 Sharp-Crested Weirs for Open Channel Flow Measurement

1 × $75.00

E - 1115 Sharp-Crested Weirs for Open Channel Flow Measurement

1 × $75.00 -

×

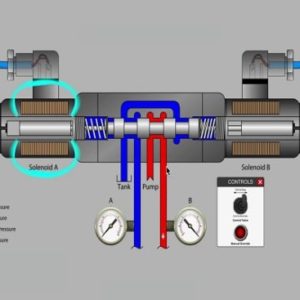

E 1102 Valve Fundamentals

1 × $100.00

E 1102 Valve Fundamentals

1 × $100.00 -

×

E - 1107 Fundamentals of Fluid Flow

1 × $150.00

E - 1107 Fundamentals of Fluid Flow

1 × $150.00 -

×

E - 1117 Introduction to Biofuels

1 × $75.00

E - 1117 Introduction to Biofuels

1 × $75.00 -

×

E - 1126 Steel Design – Basics - Updated to AISC 14th edition

1 × $5.00

E - 1126 Steel Design – Basics - Updated to AISC 14th edition

1 × $5.00 -

×

E - 1101 Solar Energy Fundamentals

1 × $100.00

E - 1101 Solar Energy Fundamentals

1 × $100.00

Subtotal: $2,780.00

E - 1105 Flow Measurement in Pipes and Ducts

E - 1105 Flow Measurement in Pipes and Ducts  E - 1106 Fundamentals of Heat Exchangers

E - 1106 Fundamentals of Heat Exchangers  E - 1114 Hydraulic Jumps and Supercritical & Non-uniform Flow

E - 1114 Hydraulic Jumps and Supercritical & Non-uniform Flow  E - 1125 Centrifugal and Positive Displacement Pump Basics

E - 1125 Centrifugal and Positive Displacement Pump Basics  E - 1111 Disinfection with Peroxone

E - 1111 Disinfection with Peroxone  E - 1104 Domestic Wastewater Treatment Overview

E - 1104 Domestic Wastewater Treatment Overview  E - 1123 Concrete Methods and principles - Full 8 Hours Course

E - 1123 Concrete Methods and principles - Full 8 Hours Course  E - 1130 Steel Design - Full 8 Hours course - Updated to AISC 14th edition

E - 1130 Steel Design - Full 8 Hours course - Updated to AISC 14th edition  E - 1103 Hydraulic Design of Storm Sewers with Excel

E - 1103 Hydraulic Design of Storm Sewers with Excel  E - 1109 Design of Small Water Systems

E - 1109 Design of Small Water Systems  E - 1113 Manning Equation - Open Channel Flow using Excel

E - 1113 Manning Equation - Open Channel Flow using Excel  E - 1108 Heat Transfer Review for Engineers

E - 1108 Heat Transfer Review for Engineers  E - 1115 Sharp-Crested Weirs for Open Channel Flow Measurement

E - 1115 Sharp-Crested Weirs for Open Channel Flow Measurement  E 1102 Valve Fundamentals

E 1102 Valve Fundamentals  E - 1107 Fundamentals of Fluid Flow

E - 1107 Fundamentals of Fluid Flow  E - 1117 Introduction to Biofuels

E - 1117 Introduction to Biofuels  E - 1101 Solar Energy Fundamentals

E - 1101 Solar Energy Fundamentals