E – 2095 Liquefied Natural Gas (LNG) – PART 7 of 10 Effects of high N2 and H2 on LNG storage

$75.00

Courses Included

LNG plants and other petrochemical plants are built to bring a return on investment to their investors through their safe operation. Their designers and engineer-led operators require technical knowledge to ensure these facilities are safe and dependable.

This training covers LNG technologies at both a technical and human resource development level. This training is needed to help you design, operate, and maintain an LNG facility; however, many LNG topics can also apply to other petrochemical plants.

It is intended to give the learner the intermediate technical knowledge needed to make informed planning, maintenance, and operating decisions to ensure plant safety, reliability, and efficiency.

In the ten lessons, details will be given on the operation of an LNG plant, refrigeration systems for liquefying, and the thermodynamics involved in producing, storing, transporting, and re-vaporizing LNG.

This is the seventh of the ten lessons. The topics covered in this lesson include understanding:

- The volatility and behavior of zeotropic mixtures (components of LNG)

- The relationship between various LNG components’ molecular mass, volatility, and temperature.

- The weathering of LNG that does not contain nitrogen, including its effect on LNG density

- The weathering of LNG that does contain nitrogen, including its effect on LNG density

- In-tank convective currents of LNG with and without nitrogen in the LNG

- The impact of hydrogen injected into LNG liquefier feed gas.

- The FERC guidelines on higher heating value, wobbe number, and inerts on interchangeability.

- Understanding LNG blending and sendout stabilization.

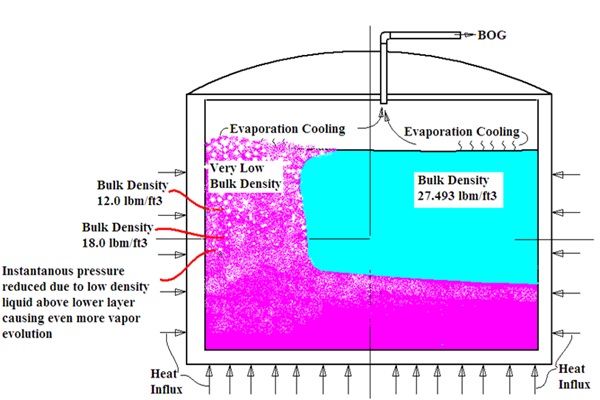

- Nitrogen-induced rollover phenomenon.

- Removal of nitrogen from LNG before storage.

- Removal of hydrogen from LNG before storage.

- The phenomenon of hydrogen stress corrosion cracking