E – 1866 Introduction to Welding and NDT

$150.00

Courses Included

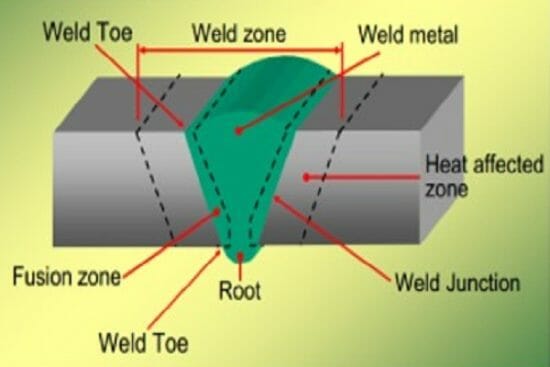

Welding is one of the most common type of joining method used in the industry. Welded components are subjected to thermal stress, which results in microscopic cracking, deformation, and hardening of the metal. Depending on the materials and the welding process, the consequences of heat input on the material surrounding the weld can compromise the material’s integrity or suitability for service.

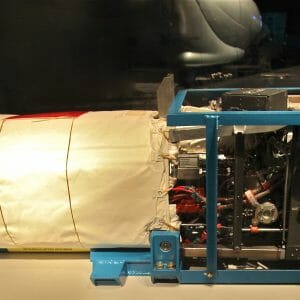

The welded materials are subjected to destructive and/or non-destructive tests to ascertain these to be fit for purpose. Destructive testing has the drawback of destroying the test object in the process. Non-destructive tests on the other hand permit evaluation of the material or component without destroying it. To appropriately apply these inspection procedures, a certain level of skill is required. These tests aren’t simply for screening out bad products; they’re also for assuring that what appears to be good is actually good.