- Course No E – 3010

- PDH Units: 3

No data found for Custom Course Number

No data found for Custom Course Units

Intended Audience: for c=Civil engineers, Structure Engineers and Forensic structural engineers

PDH UNITS: =3

This technical course explains the importance of using corrosion-resistant metal connectors and fasteners in the construction of coastal structures, areas using preservative-treated lumber, and any locations subject to contact with floodwater or windblown rain.

The intent and objective of this course is to provide licensed design professional, practicing structural engineers, forensic structural engineers, consulting engineers, building officials, educators, students or/and a licensed general contractor with all corrosion protection techniques for metal connectors and fasteners in the construction of coastal structures. This technical course explains the importance of using corrosion-resistant metal connectors and fasteners in the construction of coastal structures, areas using preservative-treated lumber, and any locations subject to contact with floodwater or windblown rain.

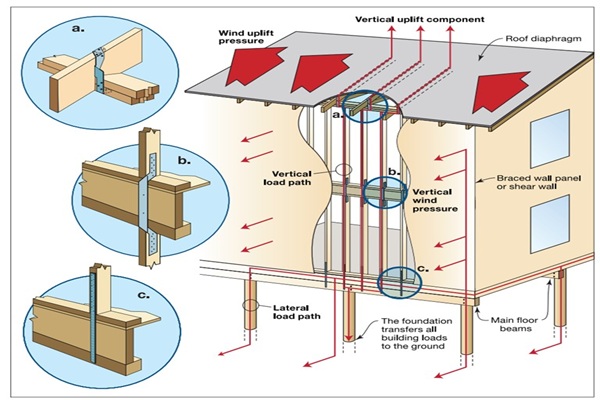

Post-disaster assessments of wood-framed buildings following natural hazard events such as high winds, floods, and earthquakes have revealed that structural failures frequently occur at connections rather than in framing members. In coastal areas, where higher moisture and humidity levels exist and buildings are exposed to salt spray, corroded metal connectors and fasteners have been observed to contribute to the loss of an adequate load path. The loss of an adequate load path often results in damage to or failure of the structure. This technical course presents guidance on addressing and avoiding the corrosion of connectors and fasteners. Unfortunately, there are not a sufficient number of references dealing with this topic, so the course was designed to be an important guide for the structural engineers working in this field.

Learning Objectives

At the successful conclusion of this course, you’ll be able to identify and discuss:- Gaining a general overview of the importance of selecting proper connectors and fasteners for a continuous load path

- Gaining a general overview of the importance of corrosion protection for lighter gauge connectors

- Gaining a general overview of the connectors that have the minimum galvanization provided by the manufacturer and that do not have corrosion resistance beyond the minimum

- Gaining a general overview of the chemicals in preservative-treated wood

- Gaining a general overview of the galvanic corrosion

- Gaining a general overview of the metal connector and fastener materials and fabrication

- Gaining a general overview of the galvanizing (the process of coating steel with zinc)

- Gaining a general overview of the standards and codes for galvanizing

- Gaining a general overview of the proprietary coatings

- Gaining a general overview of the causes of corrosion in coastal areas

- Gaining a general overview of the exposure classes for connectors and fasteners

- Gaining a general overview of the improving corrosion-resistant materials and coatings

- Gaining a general overview of the guidance for connector and fastener corrosion control

- Gaining a general overview of the summary of best practices for corrosion resistance

- Gaining a general overview of the recommendations on corrosion-resistant materials and methods

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.