- Course No E – 1971

- PDH Units: 2

No data found for Custom Course Number

No data found for Custom Course Units

Intended Audience: civil, environmental, and chemical engineers..

PDH UNITS: 2

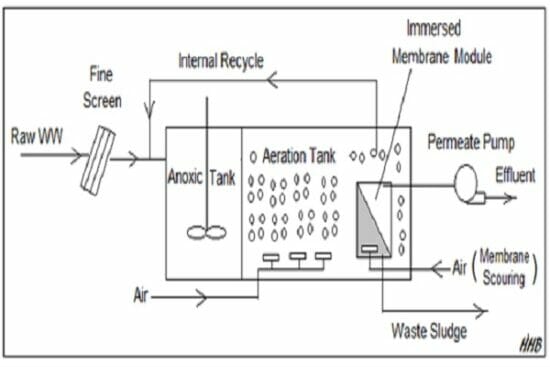

The MBR (membrane bioreactor) process uses an aeration tank similar to those used in conventional activated sludge processes, combined with membrane filtration as a replacement for secondary sedimentation. This combination can produce a very high quality effluent, typically with a more compact reactor than conventional activated sludge, but requires a higher rate of aeration than conventional activated sludge in order to keep the membranes from fouling. The current typical MBR process configuration uses a membrane module submerged in the aeration tank. This course includes discussion of process design calculations for the membrane module used in an MBR system, for an MBR aeration tank designed to provide BOD removal and nitrification, and for a pre-anoxic tank to go with an MBR BOD removal and nitrification system. This course is intended primarily for civil engineers, environmental engineers, and chemical engineers. After completing this course you will be familiar with the general components and configuration of an MBR wastewater treatment process and be able to make typical process design calculations for an MBR process.

Learning Objectives:

At the successful conclusion of this course, you will learn the following knowledge and skills:- Be familiar with the components of and general configuration of an MBR wastewater treatment process

- Know the advantages and disadvantages of an MBR wastewater treatment process in comparison with a conventional activated sludge process

- Know the type of pretreatment typically required for an MBR wastewater treatment process

- Be able to carry out process design calculations to determine the required membrane area, membrane module volume and scouring air flow rate for an MBR wastewater treatment system

- Be able to carry out process design calculations for a BOD removal/nitrification MBR process in order to determine the required aeration tank volume, sludge wasting rate, air flow rate, and alkalinity addition

- Be able to carry out process design calculations for a Pre-Anoxic Denitrification MBR process in order to determine the required pre-anoxic tank volume, the reduced oxygen/air requirement, the reduced alkalinity requirement, the anoxic tank mixing power needed, and the sludge wasting rate

Once completed, your order and certificate of completion will be available in your profile when you’re logged in to the site.

Ethics Courses

E – 1726 New Mexico Administrative Code for Professional Engineers, Title 16, Chapter 39by Mr. D. Allen Hughes, PE

E – 1865 Engineering Ethics: The Cases of Challenger and Columbia Shuttle Disasters; “Hold Safety Paramount” to Prevent Loss of Lifeby Dr. Abolhassan Astaneh-Asl, Professor Emeritus. Ph.D., PE