-

×

E - 1816 Dos & Don’ts In Steel And Connection Design

1 × $80.00

E - 1816 Dos & Don’ts In Steel And Connection Design

1 × $80.00 -

×

E - 1443 OSHA: Ground-Fault Protection on Construction Sites

1 × $25.00

E - 1443 OSHA: Ground-Fault Protection on Construction Sites

1 × $25.00 -

×

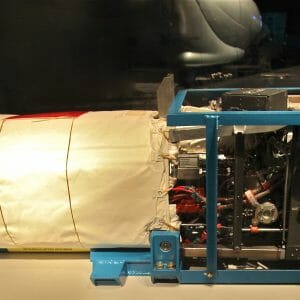

E - 1959 Remove and Replace a Bridge - Infrastructure Projects - Construction Technology

1 × $25.00

E - 1959 Remove and Replace a Bridge - Infrastructure Projects - Construction Technology

1 × $25.00 -

×

E - 1444 Operation and Maintenance of Landfill Gas Systems

1 × $75.00

E - 1444 Operation and Maintenance of Landfill Gas Systems

1 × $75.00 -

×

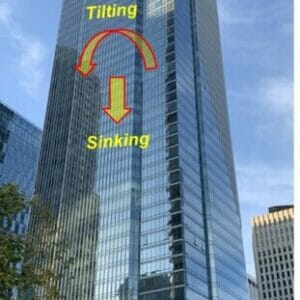

E - 1935 Engineering Ethics: The Millennium Tower Sinking and Tilting-Was the Root Cause Engineering Ethics Violations?

1 × $100.00

E - 1935 Engineering Ethics: The Millennium Tower Sinking and Tilting-Was the Root Cause Engineering Ethics Violations?

1 × $100.00 -

×

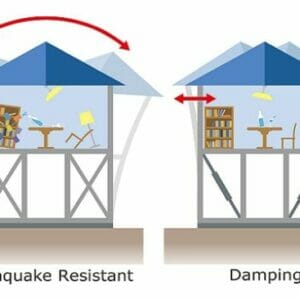

E - 1951 Damping in structures. The different approaches adopted in Seismic and Wind Engineering and a new unifying theme

1 × $95.00

E - 1951 Damping in structures. The different approaches adopted in Seismic and Wind Engineering and a new unifying theme

1 × $95.00 -

×

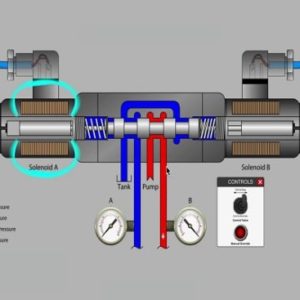

E - 1125 Centrifugal and Positive Displacement Pump Basics

1 × $75.00

E - 1125 Centrifugal and Positive Displacement Pump Basics

1 × $75.00 -

×

E - 1895 ISO 50001 -Energy Management

1 × $75.00

E - 1895 ISO 50001 -Energy Management

1 × $75.00 -

×

E - 1123 Concrete Methods and principles - Full 8 Hours Course

1 × $200.00

E - 1123 Concrete Methods and principles - Full 8 Hours Course

1 × $200.00 -

×

E - 1891 Steel Bridges- Redundancy in Design

1 × $75.00

E - 1891 Steel Bridges- Redundancy in Design

1 × $75.00

Subtotal: $825.00

E - 1816 Dos & Don’ts In Steel And Connection Design

E - 1816 Dos & Don’ts In Steel And Connection Design  E - 1443 OSHA: Ground-Fault Protection on Construction Sites

E - 1443 OSHA: Ground-Fault Protection on Construction Sites  E - 1959 Remove and Replace a Bridge - Infrastructure Projects - Construction Technology

E - 1959 Remove and Replace a Bridge - Infrastructure Projects - Construction Technology  E - 1444 Operation and Maintenance of Landfill Gas Systems

E - 1444 Operation and Maintenance of Landfill Gas Systems  E - 1935 Engineering Ethics: The Millennium Tower Sinking and Tilting-Was the Root Cause Engineering Ethics Violations?

E - 1935 Engineering Ethics: The Millennium Tower Sinking and Tilting-Was the Root Cause Engineering Ethics Violations?  E - 1951 Damping in structures. The different approaches adopted in Seismic and Wind Engineering and a new unifying theme

E - 1951 Damping in structures. The different approaches adopted in Seismic and Wind Engineering and a new unifying theme  E - 1125 Centrifugal and Positive Displacement Pump Basics

E - 1125 Centrifugal and Positive Displacement Pump Basics  E - 1895 ISO 50001 -Energy Management

E - 1895 ISO 50001 -Energy Management  E - 1123 Concrete Methods and principles - Full 8 Hours Course

E - 1123 Concrete Methods and principles - Full 8 Hours Course  E - 1891 Steel Bridges- Redundancy in Design

E - 1891 Steel Bridges- Redundancy in Design