Subtotal: $50.00

E – 1233 Repair of Rigid Pavements

$75.00

Courses Included

This course will introduce you to materials, criteria, and procedures for rapid repair of uncontrolled cracks and spalls in rigid pavements by using epoxy resin grouts, mortars, and concretes. Seven crack conditions that encompass most of the crack types that will be encountered will be discussed. This course is applicable to the repair of rigid pavements on roads and airport runways and taxiways

Course Outline

1. PURPOSE

2. DEFINITIONS

3. GENERAL PROVISIONS

4. APPROVED EPOXY MATERIALS

5. APPLICATIONS

6. EFFECTIVE TEMPERATURE AND CONDITIONING

7. AGGREGATES FOR EPOXY RESIN CONCRETES AND MORTARS

8. SAMPLING AND TESTING EPOXY RESINS

9. TRIAL BATCHES

10. FIELD MIXING AND BATCH SIZE

11. PROCEDURES FOR CONDITIONS 1 AND 2

12. PROCEDURE FOR CONDITION 3

13. PROCEDURE FOR CONDITION 4

14. PROCEDURE FOR CONDITION 5

15. PROCEDURE FOR CONDITION 6

16. PROCEDURE FOR CONDITION 7

17. PROTECTION OF REPAIRED AREAS FROM WEATHER AND TRAFFIC

18. CLEANING OF EQUIPMENT AND TOOLS

19. SAFETY AND HEALTH PRECAUTIONS

Description

This course will introduce you to materials, criteria, and procedures for rapid repair of uncontrolled cracks and spalls in rigid pavements by using epoxy resin grouts, mortars, and concretes. Seven crack conditions that encompass most of the crack types that will be encountered will be discussed. This course is applicable to the repair of rigid pavements on roads and airport runways and taxiways

Course Outline

1. PURPOSE

2. DEFINITIONS

3. GENERAL PROVISIONS

4. APPROVED EPOXY MATERIALS

5. APPLICATIONS

6. EFFECTIVE TEMPERATURE AND CONDITIONING

7. AGGREGATES FOR EPOXY RESIN CONCRETES AND MORTARS

8. SAMPLING AND TESTING EPOXY RESINS

9. TRIAL BATCHES

10. FIELD MIXING AND BATCH SIZE

11. PROCEDURES FOR CONDITIONS 1 AND 2

12. PROCEDURE FOR CONDITION 3

13. PROCEDURE FOR CONDITION 4

14. PROCEDURE FOR CONDITION 5

15. PROCEDURE FOR CONDITION 6

16. PROCEDURE FOR CONDITION 7

17. PROTECTION OF REPAIRED AREAS FROM WEATHER AND TRAFFIC

18. CLEANING OF EQUIPMENT AND TOOLS

19. SAFETY AND HEALTH PRECAUTIONS

- Learn about epoxy resins for repairing rigid pavement.

- Learn about the importance of conditioning aggregates in the preparation of epoxy resin concretes and mortars.

- Learn how to condition epoxy resin components.

- Learn how to accelerate hardening rates of epoxy binders to facilitate resumption of traffic over a repaired area.

- Learn about requirements for fine aggregate for use in epoxy resin mortars.

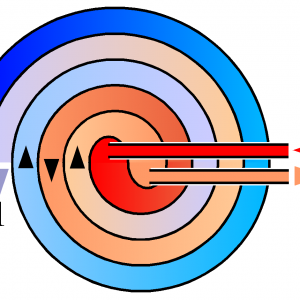

E - 1106 Fundamentals of Heat Exchangers

E - 1106 Fundamentals of Heat Exchangers